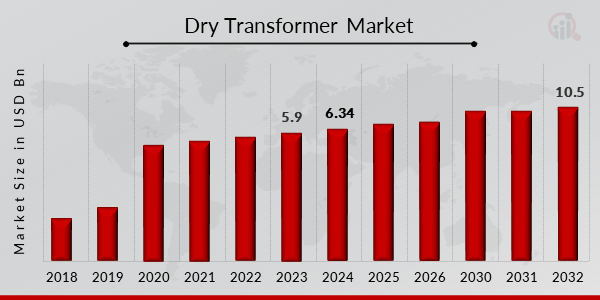

Dry-type transformers are essential in modern power distribution networks. They can manage the irregular voltage at consistent levels by step-up or step-down features. These transformers are growing due to their numerous advantages, especially as modern energy needs. According to Market Research Future, this transformer market size is expected to grow at a compound annual growth rate (CAGR) of 6.51% from 2024 to 2032.

Over the last few years, India has recorded massive growth in industrialization and urbanization that has surged the demand for Dry Type Transformers. These transformers are extremely safe, eco-friendly, compact, minimal to maintain, compatible with smart grids and advanced energy distribution systems, and more.

What is a Dry-Type Transformer?

The dry-type transformers are a special type of transformers that use air or other inert gases for cooling. They are known for their higher safety, eco-friendliness, and minimal maintenance.

They are often installed in sensitive industrial environments where the risk of fire hazards is high. These transformers quickly decrease the voltage of the conventional power circuit and generate extreme heat that requires cooling. Let’s find out the common cooling processes of dry transformers.

Dry Type Transformer Cooling Methods

A dry-type transformer uses many different cooling methods. Each method is customized to meet the requirements of particular industrial applications and cater to the environmental conditions.

Here are some of the most common techniques used by the device.

1. Natural Air Cooling (AN)

Natural Air Cooling is one of the easiest methods employed by dry-type transformers for cooling. In this method, the air is circulated naturally around the transformer. The transformer dissipates the heat generated within the transformer into the surrounding air. In this process, there is no need for any external efforts.

This cooling method is feasible for a dry type of transformer that has low capacity. It is ideal for small industries or residential projects.

2. Benefits of AN

The benefit of Natural Air Cooling is that there is no requirement for any auxiliary equipment or any moving part. Also, this method requires less maintenance and it has low operational costs.

3. Forced Air Cooling (AF)

Forced Air Cooling is another common dry transformer cooling method that includes fans or blowers to improve heat dissipation. In this method, external fans are used for blowing air over the transformer windings and core. This leads to removing heat. The method is perfect for transformers with medium and high capacity and ideal for industrial uses.

Benefits of AF

- This method ensures better cooling efficiency and is well-suited for higher load capacities.

Forced Air with Water Cooling (AFWF)

AFWF is a hybrid method meaning it involves forced air cooling. It is integrated with a water-cooled heat exchanger to remove heat efficiently. In this method, external fans are used to blow air over the transformer whereas the water-cooled system absorbs and transforms the heat.

This cooling method is ideal for high-capacity transformers and suitable for power plants and large-scale manufacturing.

Benefits of AFWF

The benefit of AFWF is that it is very impactful and meets the requirements in areas with high temperatures. It maintains lower operating temperatures.

Conclusion

These are the three most common dry-type transformer cooling methods. If you want to learn more about dry transformer cooling methods or want to buy this transformer, you can directly contact Mahendra Transformers. This company is one of the leading manufacturers and suppliers of high-quality dry transformers that perform manufacturing and testing of instruments as per Is. & Is. 1180 national and international standards of quality.

Mahendra Transformers are certified by various organizations including ISO, NSIC, IEC, CPWD, DIC, and others. With over 32+ years of expertise and successful projects, they have handled many projects all over India. These include NHPCL, NTPC Dadri, BHEL, DMRC, East Cost Railway, Konkan Railway Corporation, North Central Railway, and many more. So, choose Mahendra Transformers dry-type transformers and stay ahead in the industry.